What Is Tencel?

Tencel: A Closed Loop Fabric

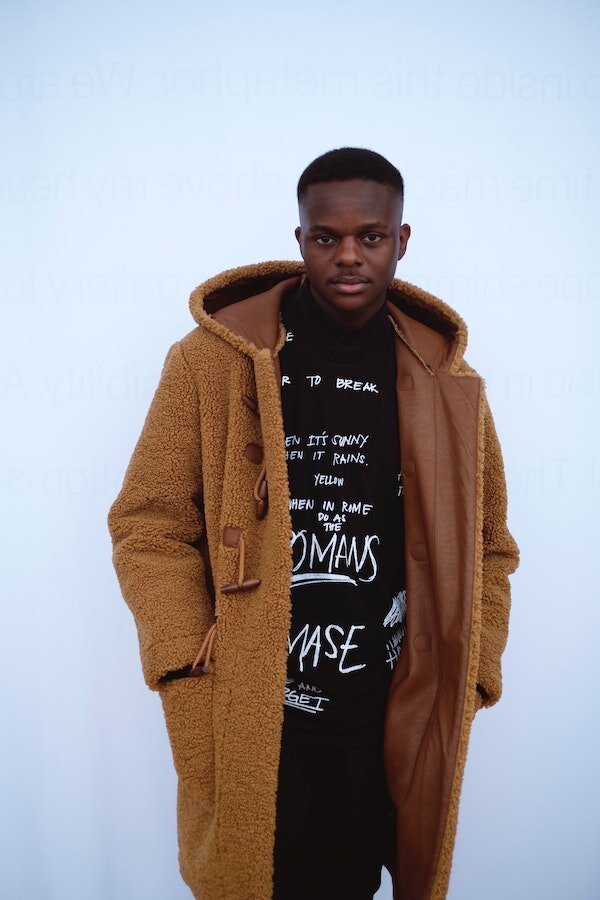

Tencel is a branded version of plant-based lyocell fabric, which is applauded by the sustainable fashion community for its low environmental impact, antibacterial qualities, and silky smooth touch. It continues to prevail in popularity due to its softness and breathability. For this reason, Tencel is often used for t-shirts, loungewear, and bedding. This fabric doesn’t wrinkle easily either, and it holds color well. It can even be combined with various fibers—like organic cotton—to enhance function and aesthetic qualities.

Major brands, including Patagonia, tentree, and People Tree, are using Tencel in their garment collections, and the naturally derived material is seemingly infiltrating the fashion industry. But where did this fiber come from, and how sustainable is it?

“Tencel is applauded by the sustainable fashion community for its low environmental impact, antibacterial qualities, and silky smooth touch.”

Understanding the TENCEL™ Trademark

You’ll often see Tencel referred to as Tencel lyocell on brand websites. Though originally invented by Courtaulds plc in 1992, it was acquired by Austrian textiles company Lenzing in the early 2000s. The company trademarked the fabric as TENCEL™ and has since expanded its line of sustainable materials, including its own modal (also branded with the TENCEL™ trademark, but it’s technically a different fabric).

All that to say, whenever you see Tencel, it’s in reference to Lenzing’s trademarked lyocell fabric. While there are other forms of generic lyocell out there, Tencel is specific to Lenzing.

And Lenzing Tencel is “produced by environmentally responsible processes from sustainably sourced natural raw material wood,” according to the company. The company keeps tabs on its sustainable practices by assessing its 700 wood suppliers annually, using FSC® (Forest Stewardship Council) Controlled Wood criteria.

The wood for Tencel is typically sourced from Eucalyptus trees. Eucalyptus is lauded as a particularly sustainable raw material for its water efficiency and ability to grow on arid land. After being chopped and debarked, the wood is broken down into pulp by amino oxide, an organic solvent. It is then pushed through a spinneret (a machine that forces the substance through small holes) to form filament fibers. Fibers are then spun into fabric.

Unlike its synthetic-heavy parent fabric, rayon, there are fewer toxic chemicals in the Tencel production process. Lenzing employs a closed loop production system to recapture and reuse these chemicals so that they don’t pose a risk to human health or the environment (similar to their closed loop viscose process).

“On the basis of the Lenzing technology, the recovery rate for this valuable and expensive chemical is more than 99 percent,” the website boasts.

Is Tencel Fully Sustainable?

For Tencel’s many attributes, the continued misconceptions about the hybrid fabric pose a problem. “Tencel” is so often used to refer to all lyocell products, forgetting that Lenzing’s branded lyocell is the only true Tencel out there. This by no means indicates that lyocell is an unsustainable material; there’s simply less transparency. And even Lenzing has a few questionable marketing claims.

“The fabric is described as biodegradable and compostable […but…] it’s ultimately dependent on what happens with the fiber once it leaves Lenzing’s hands.”

Lenzing’s Tencel fabric is described as biodegradable and compostable, and while this is technically true, it’s ultimately dependent on what happens with the fiber once it leaves the company’s hands. If a clothing brand applies toxic dyes or finishes to the fabric, it can no longer be composted or degraded organically. Additionally, like other products labeled as biodegradable, these garments can’t be dropped in a home garden or compost bucket, but they must be professionally and adequately broken down instead.

Innovative and sustainable fibers are exciting for the fashion industry, but companies must make it simpler for consumers to understand exactly how the materials are being made.

The biggest obstacle that remains, though, is the price. Not unlike most sustainable materials, Tencel can be expensive. This may be because the technology and intentional sourcing required for Tencel forces a higher cost. Either way, we’re left with an inaccessible garment for the majority of customers.

With the uncertainty of fashion supply chains and lack of adequate consumer recycling options, it’s impossible to guarantee that the environmental benefits will continue once Lenzing sends the material out into the world. However, if employed thoughtfully, Tencel can be a sustainable (and soft!) option for low-impact pieces.

Audrey Stanton was born and raised in the Bay Area and is currently based in Los Angeles. She works as a freelance writer and content creator with a focus in sustainable fashion. Audrey is deeply passionate about conscious living and hopes to continue to spread awareness of ethical consumption.